When you buy a medical device, an electric car, or even a smartphone, you don’t just pay for the product-you pay for the promise behind it. That promise is built on trust. And right now, that trust is cracking under the weight of manufacturing fears.

Quality Isn’t Just a Process Anymore-It’s a Brand Asset

In 2025, 95% of manufacturing executives said quality assurance was mission-critical. Not because they had to. But because customers noticed when it slipped. A single defective pacemaker. A battery that overheats in an EV. A sensor that fails in a ventilator. These aren’t just production errors-they’re brand killers. Companies that treat quality as a checkbox are losing. Those that treat it as a core part of their identity are pulling ahead. The ZEISS U.S. Manufacturing Insights Report 2025 found that manufacturers who integrated quality into their innovation strategy saw 28% higher profit margins by 2030. Why? Because customers don’t just want a working product. They want to feel safe using it.The Hidden Cost of Rework

Thirty-eight percent of manufacturers say the cost of rework is their biggest quality challenge. That’s not just labor. It’s material. Time. Delayed shipments. Lost customer confidence. One medical device maker in Ohio spent $1.2 million a year fixing parts that didn’t meet tolerances. They didn’t fix their process. They fixed their measurement. By switching to AI-enhanced 3D metrology systems, they cut rework by 42% in eight months. That’s not just savings. That’s trust restored. Meanwhile, another company invested $2.3 million in automated inspection tools but didn’t train their team. Result? Error rates went up 40%. The machines didn’t fail. The people did. And the brand paid the price.People Are the Weakest Link-And the Strongest Asset

Forty-seven percent of manufacturers say they can’t find skilled workers. Not just engineers. But people who understand both old-school quality checks and new digital tools. On Reddit’s r/Manufacturing forum, 87% of workers complained about inconsistent data between departments. One production manager wrote: “We’re expected to deliver aerospace-grade precision at consumer electronics speed.” The solution isn’t more robots. It’s better training. Median salaries for quality engineers with AI skills hit $98,500 in 2025-22% higher than traditional roles. Companies that invest in upskilling see 27% fewer defects reach customers. Those that don’t? They’re stuck in a cycle of blame, rework, and declining loyalty.

The Tech Gap: When Tools Don’t Talk to Each Other

Manufacturers are buying the latest tools-AI inspection software, real-time monitoring, cloud-based QMS platforms. But 61% say their new systems don’t integrate with old ones. Data sits in silos. Quality teams don’t talk to production. IT doesn’t talk to engineering. This isn’t a technology problem. It’s a culture problem. Companies that succeed use cross-functional teams from day one. Quality engineers sit with IT. Production managers join software demos. Suppliers are treated like extensions of the company-not vendors. One automotive supplier shared on LinkedIn that after aligning their supplier forecasts with their own production schedule, their supply chain resilience jumped 31%.Why This Matters to Your Brand

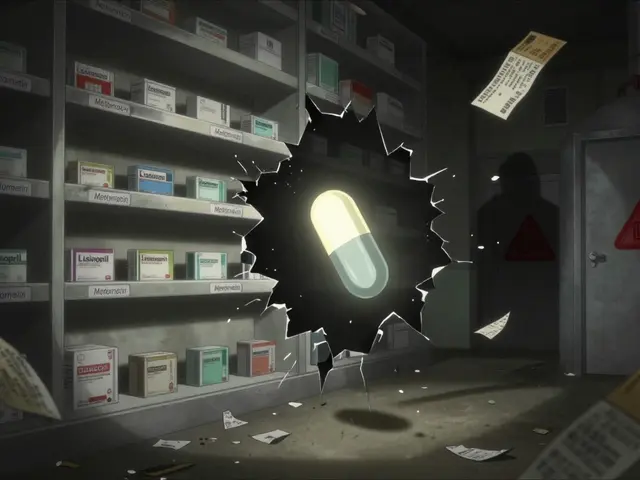

You don’t manufacture widgets. You manufacture perception. When a product fails, people don’t blame the machine. They blame the brand. They think: “If they cut corners here, what else are they cutting?” That’s brand psychology in action. Fear spreads faster than quality. Aerospace and medical device makers lead in quality tech adoption-78% and 72% respectively. Why? Because failure isn’t just costly. It’s deadly. And regulators watch. Customers watch. Investors watch. General manufacturers? Only 48% have adopted advanced quality tools. That gap isn’t just technical. It’s psychological. The public senses it. They assume the cheaper product is the riskier one-even if it’s not.

What’s Next: Predictive Quality, Not Just Inspection

The future isn’t about catching defects. It’s about stopping them before they happen. Early adopters of predictive quality analytics report 41% fewer customer-reported defects. AI doesn’t just scan parts. It learns patterns. It sees a temperature spike in a machine before a bearing fails. It flags a material batch that’s deviating from norm-before a single part is made. By 2027, 89% of leading manufacturers will use this tech. The rest? They’ll be stuck explaining why their products keep failing.Lean Isn’t Just About Waste-It’s About Trust

Sustainability and lean manufacturing aren’t buzzwords. They’re survival tools. Reducing waste means less scrap. Less scrap means lower costs. Lower costs mean better prices. But more importantly-less waste means more control. More control means fewer surprises. Fewer surprises mean more confidence. Customers don’t care about your carbon footprint unless they believe you’re in control. Lean isn’t about being green. It’s about being reliable.The Bottom Line: Quality Is the New Loyalty

In 2026, customers don’t choose brands because they’re the cheapest. They choose them because they feel safe. That safety comes from consistency. From precision. From transparency. From knowing that someone cared enough to check, double-check, and use AI to catch what humans might miss. The manufacturers who survive aren’t the ones with the biggest factories. They’re the ones who treat quality like a promise-not a policy. If your brand is built on manufacturing, then your brand’s future is built on how well you answer one question: Do you really care what happens after the product leaves your door?Why is quality assurance becoming a bigger concern for brands than ever before?

Because customers now connect product failures directly to brand integrity. A single defect in a medical device or electric vehicle doesn’t just cost money-it erodes trust. With social media and instant reviews, one bad experience can spread globally in hours. Manufacturers who treat quality as a compliance task, not a core value, are seeing customer loyalty drop. In 2025, 78% of consumers said they’d switch brands after one quality issue, up from 52% in 2020.

Can small manufacturers afford advanced quality systems?

Yes-but not all at once. Cloud-based Quality Management Systems (QMS) now cost as little as $500/month for small teams. The key is starting small: focus on one high-risk product line. Use AI-powered inspection tools that plug into existing cameras or sensors. Many vendors offer pilot programs with pay-as-you-go pricing. One small medical parts maker in Tennessee cut rework by 35% in six months using a $2,000/month cloud QMS and a $1,500 AI camera system. They didn’t need a million-dollar overhaul-just a focused step.

How do I know if my quality problems are technical or cultural?

Ask your team: Do they know why a part was rejected? If they say, “I don’t know-it just showed up in the system,” that’s cultural. If they say, “The tolerance was off by 0.002mm and the machine logged it,” that’s technical. Cultural issues show up as blame-shifting, siloed data, or resistance to new tools. Technical issues show up as repeat errors on the same machine or material. Fix culture first. No tool works if people don’t trust it.

Is AI in quality assurance just hype?

No-but only if it’s used right. AI doesn’t replace inspectors. It amplifies them. One automotive supplier used AI to reduce false positives by 29% and catch defects 37% faster. That’s not magic. That’s pattern recognition. AI spots what humans miss after 10 hours of staring at screens. But if you install AI without training staff to interpret its alerts? You’ll get more noise, not less. The best systems combine AI alerts with human judgment-not replace it.

What’s the biggest mistake manufacturers make when improving quality?

Buying tech before fixing the process. Too many companies see a shiny new inspection robot and think, “That’ll solve our quality issues.” But if your workflow is messy, your data is inconsistent, and your team doesn’t understand why quality matters, the robot just becomes another expensive paperweight. The best manufacturers start with a simple question: “What’s the one thing that keeps breaking?” Then they fix that. Then they add tech. Not the other way around.

How does quality affect pricing and customer perception?

Customers are willing to pay more for perceived reliability. A study by Forrester showed that buyers paid 15-22% more for products from brands with visible quality certifications and transparent testing data-even if the product was identical to a cheaper competitor. Why? Because fear of failure outweighs the cost of overpaying. That’s brand psychology. When customers see a company investing in precision, they assume it’s careful in other areas too. Quality isn’t a cost. It’s a signal.

Vinayak Naik

Yo, this post hit different. I work in a tiny shop in Bangalore and we’re still using calipers from 2012, but we just slapped on a $1,200 AI camera that reads defects like a psychic. No fancy ERP, no robot army-just one guy who stares at screens like he’s reading tea leaves and now our rejects dropped 40%. Quality ain’t about budget, it’s about heart. And maybe a little bit of caffeine.

Kiran Plaha

That Ohio company fixing measurement instead of process? That’s the whole story right there. So many think tech fixes everything. Nah. People fix everything. Tech just helps.

Amy Le

USA still leads in quality. Everyone else is just copying our systems while blaming ‘culture’ for their failures. 🇺🇸🔥

Pavan Vora

Wow... this is so true... I mean, seriously... you know? Like, in India, we have so many small factories... and they just... don’t talk to each other... and then... the parts fail... and everyone blames the machine... but it’s the process... and the training... and the... ugh... it’s complicated...

Indra Triawan

I just feel so sad about all this... like, imagine working your whole life to make something perfect, and then someone just... throws it away because a number was off by 0.002? It’s not just a defect... it’s a soul-crushing moment... 😔

Tom Swinton

Let me tell you something-this isn’t just about manufacturing, this is about human dignity. When you treat quality like a checklist, you’re telling your team their judgment doesn’t matter. When you invest in training, you’re saying, ‘I believe you can do better.’ And guess what? They do. I’ve seen it. A guy in Wisconsin, 58 years old, never touched an AI tool until last year. Now he’s the one catching defects no one else sees. Because he cared. Because someone gave him a chance. That’s the real ROI. Not the machine. Not the software. The person.

Venkataramanan Viswanathan

It is imperative to recognize that the integration of advanced quality assurance technologies must be preceded by the establishment of a coherent operational framework. Without alignment among departments, technological investments yield diminishing returns. Furthermore, the human factor remains non-negotiable in the quality ecosystem.

Kelly Beck

Y’all are overcomplicating this 😊 You don’t need a $2M robot. You need one person who actually cares. One person who says, ‘Wait, this doesn’t feel right.’ And then you listen. That’s it. That’s the whole secret. I’ve seen it. A nurse in a hospital used to catch defective IV pumps because she noticed the click sounded ‘off.’ No sensors. Just her. Trust your people. They’re smarter than your software.

Katie Schoen

So… we spent $2.3M on robots… and the error rate went up? 😅 classic. Someone just bought a Ferrari and then tried to drive it with a stick shift while blindfolded. The car’s fine. The driver? Not so much.

Beth Templeton

AI won’t fix dumb people. Stop buying tech. Start firing them.

Dana Termini

I think the real issue is we’re treating quality like a problem to solve, not a value to live by. It’s not about tools or budgets-it’s about whether you believe your work matters. And if you don’t… no system will save you.

Isaac Jules

Of course quality is a brand asset. But let’s be real-most companies don’t care until a lawsuit hits. Then they panic, buy a $5M system, and call it a day. Meanwhile, the same people who ignored the warnings are still in charge. This isn’t a quality crisis. It’s a leadership failure. And the worst part? They’ll do it again.